Radiation Shielded Wall Panels – Medical, Industrial, and Nuclear Applications

Risdom Tech – Professional Radiation Protection Supplier

📦 Product Summary

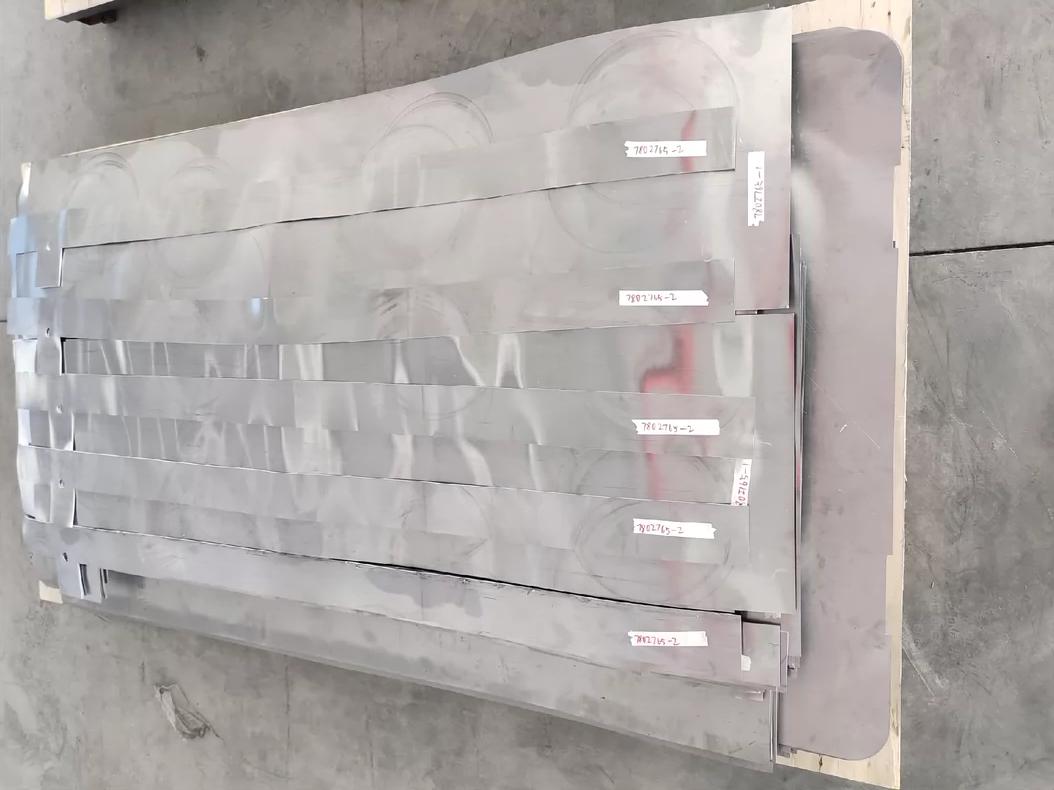

Lead lined sheetrock, also known as lead backed drywall, is a practical shielding solution for constructing radiation-protected walls and partitions. It combines standard gypsum board with a bonded lead sheet, providing a smooth surface ready for finishing and compliant with safety standards.

🔍 Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | Lead Lined Sheetrock (Lead Backed Drywall) |

| Lead Thickness Range | 1/32” to 1/8” (0.8 mm to 3.0 mm) |

| Lead Equivalency (Pb) | 0.5 mmPb to 3.0 mmPb (customizable based on radiation level) |

| Drywall Thickness | 1/2” (12.7 mm) or 5/8” (15.9 mm), fire-rated options available |

| Panel Sizes | Standard: 4’ x 8’ (1220 mm x 2440 mm) Extended: 4’ x 10’ / 12’ |

| Lead Lamination | Full-surface factory bonding |

| Edging | Square or tapered |

| Surface Finish | Ready for taping, painting, tiling |

| Optional Fire Rating | Type X drywall core (UL rated) |

| Matching Accessories | Lead batten strips, electrical box shields, lead discs, outlet covers |

| Installation Notes | Lead-to-lead overlap required, fasteners to be covered with lead discs |

🏥 Application Areas

| Sector | Example Use Cases |

|---|---|

| Medical | X-ray rooms, CT suites, dental clinics, fluoroscopy areas |

| Industrial | NDT enclosures, weld inspection labs, cargo scanning facilities |

| Nuclear | Isotope storage, shielded labs, hot cells, control rooms |

| Research | Particle testing chambers, low-dose radioactive environments |

⚙️ Installation Notes

-

Panels must be installed with lead overlap at all joints

-

Use lead batten strips behind vertical seams for continuous shielding

-

All screw heads should be covered with lead buttons or discs

-

Coordinate with other radiation components (doors, glass, windows)

-

For compliance, we recommend installation by trained radiation shielding contractors

✅ Why Choose Risdom Tech?

-

🔧 Customized Production – Lead thickness, panel size, and shape

-

📦 Efficient Packing – Palletized and wrapped for global export

-

🧾 Compliance Assured – ASTM, IEC, and local safety codes

-

🌍 Worldwide Service – Fast delivery to medical and industrial sites across the globe

-

👷 Full System Support – Pair with Risdom Tech’s lead-lined doors, windows, and glass

📄 Sample Specification Sheet

Want to include our technical sheet or lead equivalency chart in your tender?

✅ Available on request — just email us: 4118@88.com

📩 Request a Quote

Let us help you plan your next radiation-safe space.

📧 Email:4118@88.com

📞 Phone: + (86) 18906357155

🌐 Website: www.risdomtech.com

📝 → Send Us an Inquiry Now