📒 Also Known As:

-

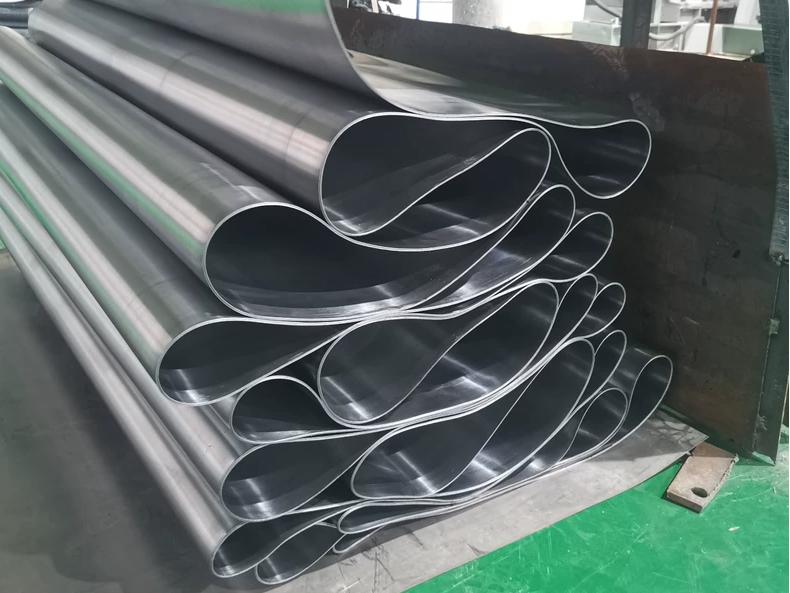

Lead Radiation Panels

-

Lead Shielding Sheets for Industry

-

Industrial Lead Wall Modules

-

Radiation Barrier Lead Plates

-

Lead-Lined Industrial Blocks

📐 Technical Specifications

| Item | Specification |

|---|---|

| Core Material | High-purity rolled lead (99.94% minimum) |

| Lead Thickness Range | 3 mm (1/8”) – 75 mm (3”) or custom |

| Panel Dimensions | 1000×2000 mm standard; custom sizes available |

| Surface Finish | Raw lead / Galvanized steel cladding / Stainless cover / Powder coat |

| Panel Structure | Single solid lead / Lead bonded to steel / Lead-wood composite |

| Shielding Rating | Up to 200 kVp X-ray and gamma protection |

| Installation Style | Wall-mounted / freestanding / interlocking system |

| Fire Resistance | Fire-retardant steel options upon request |

| Optional Reinforcement | Internal support frame or structural steel inserts |

| Compliance Standards | ASTM B749, NCRP 147, DIN 25407, ISO radiation safety protocols |

🏗 Common Use Scenarios

| Industry | Application |

|---|---|

| Non-Destructive Testing | Shielding for radiographic inspection rooms (RT rooms) |

| Power Generation | Nuclear reactor wall protection, particle control shielding |

| Pharmaceutical | Clean room radiation isolation for isotope use |

| Mining & Metallurgy | Shielding against naturally occurring radioactive materials (NORM) |

| Research Facilities | Particle acceleration and test chamber containment |

| Military / Defense | Storage bunkers for radiation equipment or weapon components |

⚙️ Customization Options

| Option | Details |

|---|---|

| Thickness Tolerance | ±0.3 mm standard; tighter tolerances on request |

| Cladding Material | Cold-rolled steel, aluminum, stainless, or marine-grade finishes |

| Mounting Hardware | Bolted flanges, slide tracks, welded anchors |

| Seam Sealing | Lead-on-lead overlaps or caulk-sealed joints for continuous protection |

| Mobility | Optional castors or forklift brackets for mobile configurations |

| Labeling | Custom serial number engraving, safety markings, or company logo |

📦 Packaging & Logistics

| Packing Method | Foam-wrapped with reinforced wooden crates |

|---|---|

| Weight Handling | Forklift-ready skids; each crate labeled with weight and center point |

| Shipping Format | Flat-packed or pre-assembled modules depending on site constraints |

| Lead Time | 10–18 working days for standard panels; faster for repeat orders |

| Export Documents | MSDS, RoHS declaration, lead purity certificate, commercial invoice |

✅ Why Risdom Tech?

-

🧪 Material Certainty – Certified high-purity lead, with consistent shielding performance

-

🏗 Heavy Industry Ready – Built for rugged sites with heavy-duty support options

-

🔧 Custom-Fit Panels – Match your wall sizes, shielding targets, and install method

-

🌍 Trusted Worldwide – Used in facilities across Asia, Europe, the Middle East, and the Americas

-

📞 Fast Quotation Turnaround – Just send your layout drawing or target shielding thickness

📩 Ready to Inquire?

📧 Email: 4118@88.com

📁 Need drawings or cut sheets? Send us your layout and we’ll reply within 24 hours.