Also known as:

-

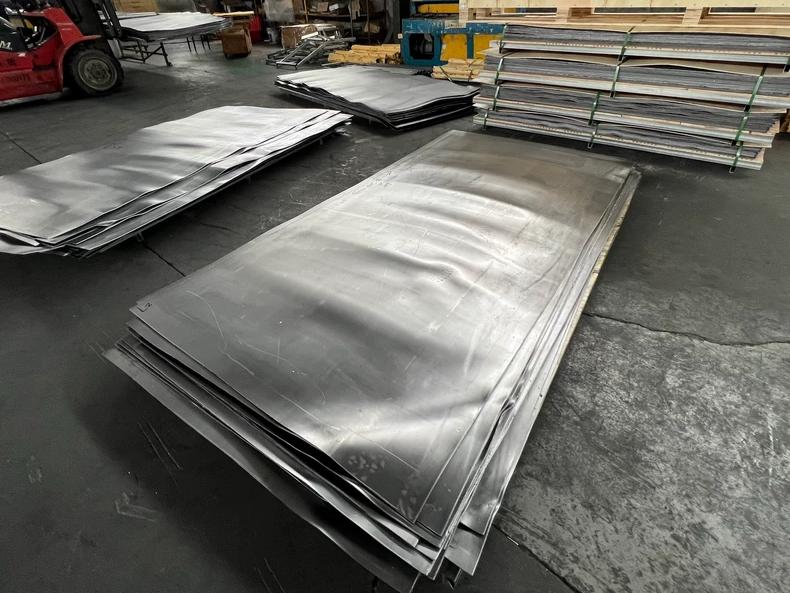

Radiation shielding plates

-

Lead shielding panels

-

Radiation protection slabs

-

Lead-backed panels

-

Shielding plates for X-ray and nuclear facilities

📐 Technical Specifications

| Specification | Details |

|---|---|

| Material | High-density lead or lead composite |

| Lead Thickness | 1/32″ (0.8 mm) to 1/4″ (6.35 mm) – customizable |

| Plate Sizes | Standard: 1000×1000 mm, 1000×2000 mm, 1220×2440 mm; custom sizes available |

| Density | 11.34 g/cm³ for pure lead |

| Weight | ~11.34 kg per square meter for 1 mm thickness |

| Fire Resistance | Non-combustible |

| Surface Finish | Smooth, brushed, or textured |

| Compliance | Meets ASTM, NCRP, and local radiation shielding standards |

| Melting Point | 327.5°C |

| Hardness | Soft or semi-hardened lead available |

| Edge Treatment | Optional deburring or chamfering for easy installation |

🏥 Common Applications

| Industry | Application |

|---|---|

| Healthcare & Medical | X-ray rooms, CT scan areas, radiation therapy rooms, and fluoroscopy barriers |

| Nuclear Power | Reactor shielding, waste storage facilities, and radiation testing chambers |

| Laboratories | Research labs for controlled radiation environments and protective barriers |

| Industrial Manufacturing | Protection in radiation exposure areas, such as industrial inspection booths |

| Security & Defense | Screening areas for radiation detection and security protocols |

| Construction | Radiation protection in building structures for sensitive environments |

🔧 Customization Options

| Feature | Choices |

|---|---|

| Material | High-purity lead or lead composite for additional strength and durability |

| Plate Thickness | From 1/32″ (0.8 mm) to 1/4″ (6.35 mm), customizable for different shielding needs |

| Size | Customizable dimensions based on project requirements |

| Surface Treatment | Available in smooth, brushed, or textured finishes |

| Pre-Drilled Holes | Optional pre-drilled holes for mounting or installation |

| Edge Processing | Optional chamfered or deburred edges for easy handling and installation |

🚚 Packaging & Logistics

| Aspect | Details |

|---|---|

| Weight per Unit | 11.34 kg per m² (for 1 mm thickness) |

| Handling | Use forklift or crane for large shipments; handle with care for thinner plates |

| Storage | Store in dry, cool conditions to avoid moisture exposure |

| Export Packaging | Shrink-wrapped and securely packed for international shipping |

| Documentation | COA (Certificate of Analysis), Radiation Shielding Test Reports, and MSDS |

| Lead Time | Typically 7-10 days for standard orders, 14-20 days for custom requests |

✅ Why Choose Risdom Tech

-

Certified Materials: We use only high-quality lead with full traceability and certifications.

-

Custom Sizes & Thicknesses: Tailored to fit your specific radiation shielding needs.

-

Global Reach: Our products are exported worldwide with streamlined logistics and documentation.

-

Quick Response: Fast turnaround on quotes and orders to meet tight project deadlines.

-

Expert Support: Dedicated technical support to guide you through your shielding project.

📩 Request a Quote or Sample

📧 Email: 4118@88.com

💼 For custom sizes, specific lead time, or other inquiries, feel free to reach out with your specifications.